- Acorn Welding Inspector Level 1 - Textbook

- Certified Pipeline Welding Inspector Course

- Saiw Welding Inspector Level 1 Jobs

- Welding Inspector Level 1 Exam Questions

Welder certification, (also known as welder qualification) is a process which examines and documents a welder's capability to create welds of acceptable quality following a well defined welding procedure.

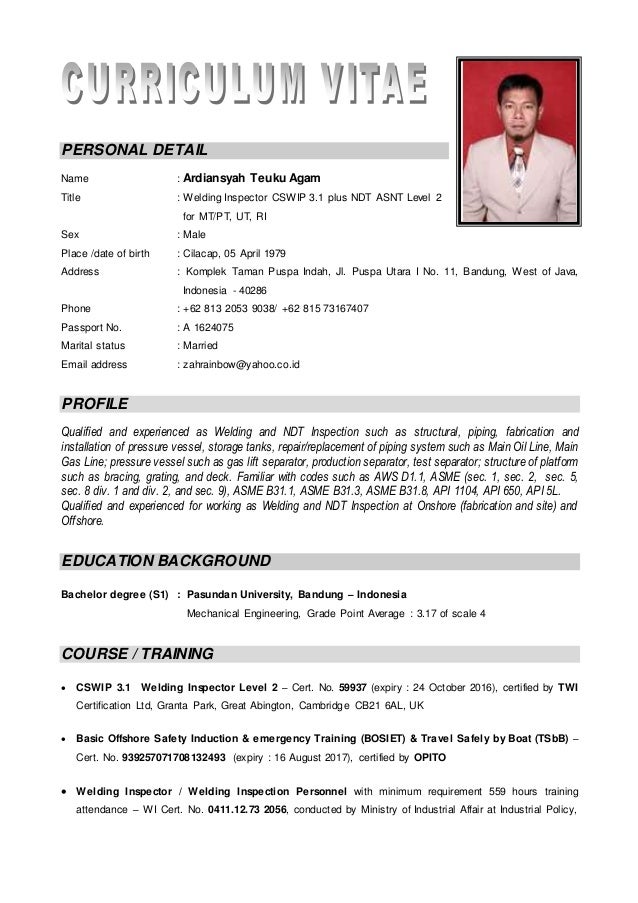

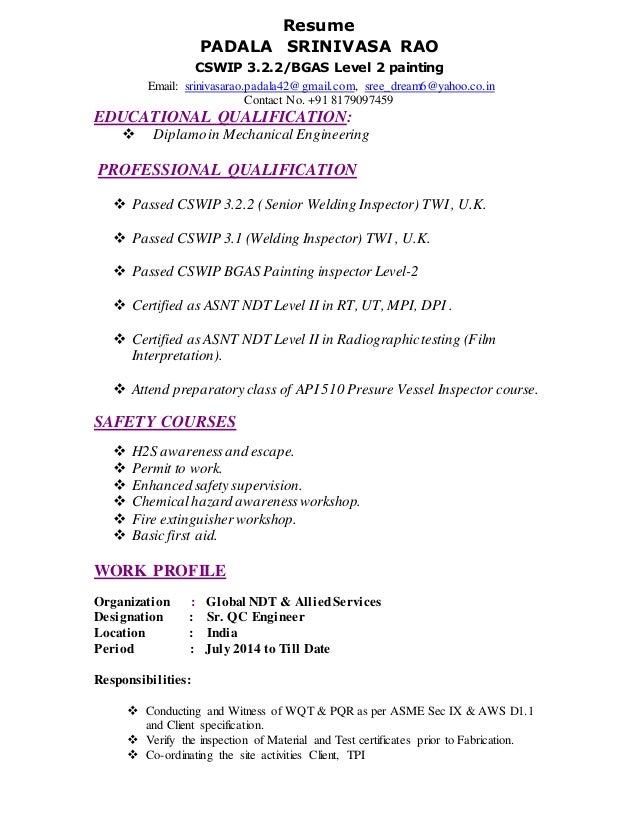

Welding Inspector / Assessor Cape Town Region R15000 to R22000. The Welding Instructor will perform a variety of routine duties, as needed, to teach structural fabricating fabricating, repair and maintenance, MIG, TIG, and ARC welding and cutting and plasma cutting to learners from by passing on your knowledge and experience in welding which includes the following. CSWIP 3.1 Welding Inspector Pre Training In Chennai-India. 22 Days PreCoching + 5 Days Seminar with 100% past passing training expertise. 3.1 welding inspector preparatory course is giving quality welding inspection training to personnel who having welding experience and qualification (welding educational background) to make professional development. CSWIP 3.1 (WELDING INSPECTOR) MULTIPLE CHOICE QUESTIONS. N3 Technical, Trade Test, 5 years power station experience and a welding inspector level 2 certificate (SAIW Certification).

Method[edit]

Welder certification is based on specially designed tests to determine a welder's skill and ability to deposit sound weld metal. The main part of the welder's test consists of welding one or more test coupons which are then examined using non-destructive and destructive methods. The extent of certification is described by a number of variables, which include the specific welding process, type of deposited metal, thickness, joint design, position, backing, and others. Most often, the test is conducted in accordance with a particular code. Depending on product requirements the test can be administered under the auspices of a national or international organization, such as the American Welding Society (AWS), or American Society of Mechanical Engineers (ASME), but manufacturers may specify their own standards and requirements as well. Most certifications expire after a certain time limit, and have different requirements for renewal or extension of the certification.

In the USA, welder qualification is performed according to AWS D1.1,[1] ASME Section IX[2] and API 1104[3] standards, which are also used in some other countries. Some States have their own Welder Qualifications that supersede AWS Qualifications, but most defer to AWS, ASME or API.

In Canada, welder qualification is carried out according to CSA Standards and ASME.[2] The ASME code is typically used for pressure vessel and pressure piping applications, and CSA Standards are used for structural, general manufacturing and non-pressure applications. There are 3 major CSA Standards to which welders may be qualified: CSA W47.1[4] for steels (including stainless steels), CSA W47.2[5] for aluminum, and CSA W186[6] for reinforcing bars. Under these CSA standards, welder qualification testing is carried out every 2 years by the Canadian Welding Bureau to ensure ongoing competence.

In Europe, the European Committee for Standardization (CEN) has adopted the ISO standards on welder qualification (ISO 9606),[7] to replace the old European EN 287 series.[8] Operators of automated welding systems are certified according to EN 1418.[9] In Europe welders are often certified by third party Personnel Certification Bodies, like The Welding Institute (TWI/CSWIP).[10] Welders involved in the manufacture of equipment that falls within the scope of the Pressure Equipment Directive must be approved by a competent third party which may be either a notified body or a third-party organization recognized by a Member State.[11]

Once a welder passes a test (or a series of tests), their employer or third party involved will certify their ability to pass the test, and the limitations or extent they are qualified to weld, as a written document (welder qualification test record, or WQTR). Normally this document is valid for a limited period (usually for two years), after which the welder must be retested. However some Qualifications are only valid for a single project, while others are unlimited as long as welders do not go beyond a specified length of time without performing that specific type of welding (this period is typically 6 months). Welders must maintain a log to demonstrate they have maintained their Qualifications.

Welding inspector certification[edit]

In addition to welders and welding machine operators, there are also schemes to independently certify welding inspectors and related specialities. The duties of the welding inspector are described in ISO 14731;[12] however the requirement for inspector certification are not standardized, so there are differences in requirement between the various schemes. Some notable schemes established by personnel certification bodies are those of the American Welding Society, of the British Institute of Non-Destructive Testing (PCN), of The Welding Institute (CSWIP) and of the Canadian Welding Bureau (CSA W178.2).

The American Welding Society offers the following programs:[13]

- Certified Associate Welding Inspector

- Certified Welding Inspector

- Senior Certified Welding Inspector

- Certified Radiographic Interpreter [14]

The British Institute of Non-Destructive Testing offers three levels of certification:[15]

- PCN Level 1

- PCN Level 2 Weld Inspection

- PCN Level 3 Weld Inspection with radiographic interpretation

The Welding Institute (TWI) in the United Kingdom offers the following certification scheme:[16]

- CSWIP 3.0 (Level 1): Visual Welding Inspector

- CSWIP 3.1 (Level 2): Welding Inspector

- CSWIP 3.2 (Level 3): Senior Welding Inspector; with or without radiographic interpretation (3.2.1 or 3.2.2 respectively)

The Canadian Welding Bureau offers the following programs:[17]

- Level 1 Certified Welding Inspector

- Level 2 Certified Welding Inspector

- Level 3 Certified Welding Inspector

The BINDT/PCN and TWI/CSWIP schemes are accredited by UKAS under ISO/IEC 17024. There are many other general schemes, as well as sector specific schemes.

In 2008, the American Petroleum Institute introduced the API 577 Advanced Welding Inspection and Metallurgy programme of certification. Certification is issued following the successful completion of a multiple choice exam which is based on the recommended practice document API 577. Certification identifies the candidate as a 'Welding Inspection and Metallurgy Professional', as opposed to a certified welding inspector under other programmes.[18]

See also[edit]

References[edit]

- ^AWS D1.1/D1.1M: 'Structural Welding Code — Steel' (section 4C)

- ^ abASME Boiler and Pressure Vessel Code section IX: 'Qualification Standard for welding and brazing procedures, welders, brazers and welding and brazing operators'. Article III: Welding Performance Qualifications.

- ^API 1104: 'Welding of pipelines and related facilities', part 6

- ^CSA Standard W47.1: Certification of companies for the fusion welding of steel (2009)

- ^CSA Standard W47.2: Certification of companies for the fusion welding of aluminum (2011)

- ^CSA W186: Welding of Reinforcing Bars in Reinforced Concrete Construction (1990)

- ^EN ISO 9606: 'Qualification test of welders — Fusion welding (ISO 9606)' four parts

- ^EN 287: 'Qualification test of welders — Fusion welding'

- ^BS EN 1418: 'Welding personnel. Approval testing of welding operators for fusion welding and resistance weld setters for fully mechanized and automatic welding of metallic materials' (1998)

- ^'Certification Scheme for Personnel - Welders'. The Welding Institute. Retrieved 2013-07-04.

- ^'Directive 2014/68/EU of the European Parliament and of the Council of 15 May 2014 on the harmonisation of the laws of the Member States relating to the making available on the market of pressure equipment', Official Journal L 189, 2014-06-27, Article 24 and Annex I, item 3.1.2

- ^BS EN ISO 14731: 'Welding coordination — Tasks and responsibilities' (2006), paragraphs 3.4, B.12, B.13, B.14

- ^AWS QC1: Standard for AWS Certification of Welding Inspectors (2007)

- ^AWS QC15: 'Specification for the Certification of Radiographic Interpreters' (2008)

- ^PCN WI: Specific requirements for the certification of personnel for weld inspection, Issue 3.A (2007)

- ^CSWIP-WI-6-92: Requirements for the Certification of Visual Welding Inspectors (Level 1), Welding Inspectors (Level 2) and Senior Welding Inspectors (Level 3) (fusion welding) in accordance with the requirements of BS EN ISO 17637:2011 (2011)

- ^CSA Standard W178.2: Certification of Welding Inspectors(2008)

- ^API 577 – Advanced Welding Inspection & Metallurgy Professional Program - American Petroleum Institute. Retrieved 27 April 2015.

External links and further reading[edit]

- Davis, A. (July 2003). 'Welder Qualification Standards - Philosophy and Feedback'(PDF). AWS Welding Journal (PDF): 14–16. Retrieved 2013-12-15.

- Welding Inspection Handbook (3rd ed.). Miami, FL: American Welding Society. 2000. ISBN0-87171-560-0.

- 'EWF Guide to deal with the transition from EN 287-1 to EN ISO 9606-1 as efficiently as possible (EWF-654-13)'(PDF) (PDF). European Federation for Welding, Joining and Cutting (EWF). 2013. Retrieved 2013-12-15.

SAMPLE JOB DESCRIPTION

Welding Inspector - CSA Level 1 or AWS CAWI

Acorn Welding Inspector Level 1 - Textbook

Description

Reporting to the QA/QC Supervisor (CSA Level 2/AWS CWI), the welding inspector would be responsible for implementing and maintaining quality programs and welding inspection duties by adhering to standard quality operational policies and procedures.

Certified Pipeline Welding Inspector Course

Duties and Responsibilities

- Review the welding procedure specification and inspection requirements prior to welding.

- Prior to and during welding, verify that the specified base metal(s) and welding filler metal(s) are used.

- Verify that the specified joint preparation and fit-up used prior to welding.

- Monitoring and inspect all work performed by tackers and welders and/or welding operators.

- Inspect and evaluate welds according to specified inspection procedures, standards, codes, and drawings.

- Record welding inspection results that were witnessed and prepare associated report.

Saiw Welding Inspector Level 1 Jobs

Certification, Knowledge, and Experience Requirements

Welding Inspector Level 1 Exam Questions

- CSA W178.2 Level 1 or AWS CAWI with at least 1 year of experience in a manufacturing, repair, or operating facility that involves welding.

- Good knowledge of welding processes, layout and fitting, base metals, filler metals, heat treatment, weld testing, and fabrication planning is required.

- Good knowledge of the weldability of ASME P-No. 1 base metals (carbon steels) is required.

- Some knowledge the weldability of P-No. 3, 4, and 5A alloy steels and P-No. 8 stainless steels would be an advantage.

- Good knowledge of welding inspection and related NDE methods (MT, PT, UT, and RT), including ASME Sec. V, are required.

- CSA and ASME Code experience is required, where multiple code endorsement certifications would be an advantage.